The following algorithms are implemented within the UNIMI.CropQuality component, that can be downloaded at...

To perform in silico evaluations of rapeseed quality during the growing season, an already published library of models for the estimation of crop quality (Cappelli et al., 2014) was extended by including specific algorithms for the assessment of both content and composition of rapeseed oil and was then coupled with WOFOST_Rapeseed. The implemented approaches were derived and adapted from recent literature (Baux et al., 2008 and 2013), which proposed a set of models mainly driven by meteorological conditions experienced by the crop during the ripening period (i.e. temperature, rain amounts).

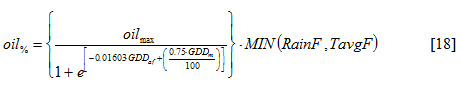

The oil accumulation in kernels follows a sigmoid pattern as function of thermal time accumulation since flowering, reaching a plateau near the time of maturity. The estimation of potential oil content thus calculated is then daily adjusted taking into account the most limiting factor between temperature and cumulated rainfall amount, with the latter used as a proxy for possible water stress. (Equation 18).

Where oilmax = maximum oil content of tested rapeseed variety (% of dry matter, parameter), GDDaf = growing degree-days from the onset of flowering (°C day -1), GDDm = growing degree-days to reach maturity (°C day-1, parameter), RainF and TavgF (unitless) = daily limiting factors to potential oil content accumulation, respectively due to cumulated rainfall and average temperature experienced by the crop during ripening phase.

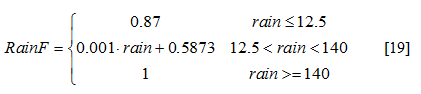

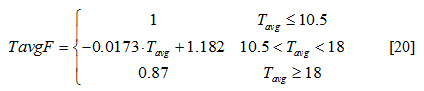

The abovementioned reduction factors were both derived through normalization of literature data (Walton et al., 1999) by means of linear functions, which can assumes values ranging between 0.87 (highest impact) and 1 (no impact) according to equations 19 and 20.

Where rain and Tmean = cumulated rainfall (mm) and average air temperature (°C) from the onset of flowering stage.

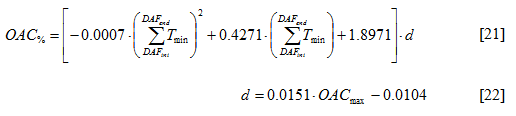

Since no information was available on both the relative weight of each factor and the possible interactions between the two, their effects were separately considered and the less impact one was then excluded. The modelling approaches implemented for the determination of oilseed FA composition are focused on the estimation of the relative content of (i) oleic, (ii) linoleic and (iii) α –linolenic unsaturated FA. The oleic acid content (OAC) in the kernel (% on total fatty acids) is estimated as a function of the minimum air temperature perceived by the crop during the post-flowering temperature-sensitive period, using a quadratic function (Equation 21). Since the model parameterizations provided by the authors for varieties with high and medium OAC resulted in curves with the same shape and slope, We assumed that both varieties had the same response to temperature within the sensitive period. Therefore we implemented as default the parabolic function parameterized as for medium OAC varieties, which can be then shifted along the y-axis according to the varietal maximum oleic acid content edited by the user (Equation 22).

Where OAC % =relative oleic acid content of rapeseed kernel (% of total fatty-acids), DAFini and DAFend = number of days since the onset of flowering which identify, respectively, the beginning and the end of the crop sensitive period to thermal injuries, Tmin = minimum air temperature (°C), d = translation coefficient allowing to shift the vertex of the parabola according to the maximum oleic acid content typical for the simulated rapeseed cultivar (unitless), OACmax = maximum oleic acid content of rapeseed variety selected for simulations (% of total fatty-acids, parameter).

Furthermore the opportunity to set a minimum value for the OAC in the kernel is given to the user.

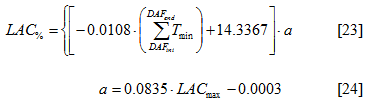

As in the previous case, also the linoleic acid content (LAC) is calculated as function of the cumulated minimum air temperature during the post-flowering sensitive period to temperature, but making use of a linear equation approach instead of the quadratic one (Equations 23 and 24).

Where LAC% = linoleic acid content in the kernel of rapeseed variety simulated by the user (% of total fatty-acid), DAFini and DAFend = number of days after flowering which identify, respectively, the beginning and the end of crop sensitive period to temperature (days, parameters), Tmin = minimum air temperature (°C), a = translation coefficient allowing to shift the equation of straight line along the y-axis according to the maximum linoleic acid content typical for the simulated rapeseed cultivar (unitless), LACmax = maximum linoleic acid content typical for tested variety(% of total fatty-acids, parameter).

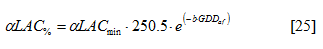

For the estimation of α-linolenic acid content (αLAC), three alternative models were implemented, respectively based on (i) logistic, (ii) quadratic and (iii) linear approaches. The logistic model estimates the αLAC in the kernel depending on both the thermal time accumulated from the onset of flowering and the minimum αLAC peculiar for the tested rapeseed cultivar. (Equation 25).

Where αLAC% = α-linolenic acid content of simulated variety (% of total fatty-acids), αLACmin = minimum α-linolenic acid content, typical for the simulated variety (% of total fatty-acids, parameter), GDDaf = accumulated growing degree-days from the onset of flowering, b = empiric coefficient of the equation.

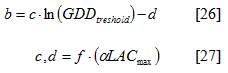

The equation proposed by developers was then modified by adding two parameters, which enables the user to define both (i) the growing degree days threshold beyond which the rate of αLAC accumulation starts to decrease and (ii) maximum value for αLAC, according to varietal characteristics of cultivar to be simulated. Once these parameters values are set by the user, the coefficient b of the logistic model (Equation 25) is automatically recalculated through the equations 26 (logarithmic) and 27 (quadratic) in order to adapt the default parameterized function to the features of tested variety, but keeping the shape of the curve unchanged.

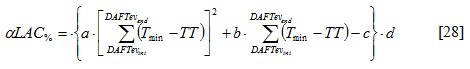

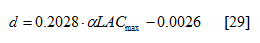

The quadratic approach calculates the αLAC as function of the number of days with minimum air temperature below a critical threshold temperature for optimal synthesis of αLAC within the post-flowering temperature-sensitive period (Equations 28 and 29).

Where αLAC% = α-linolenic acid content (% of total fatty-acids), DAFini and DAFend = number of days after flowering which identify, respectively, the beginning and the end of the sensitivity period to high temperatures, , Tmin = minimum air temperature (°C), TT = parameter representing the upper limit of critical temperature for optimal synthesis of α-linolenic acid, a and b = empiric coefficients (unitless); d = translation coefficient of parabola (unitless).,

As in the case of oleic acid content (Equations 21 and 22), the default parameterized quadratic equation is automatically corrected according to the varietal maximum αLAC edited by the user (Equation 29).

Where αLACmax = maximum α-linolenic acid content typical for the variety simulated by the user (% of total fatty-acids, parameter).

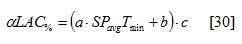

The third approach estimates the αLAC in the kernel using a linear function having as independent variable the average value of minimum air temperature experienced by the crop during the post-flowering period of maximum sensitivity to high temperature (Equation 30 and 31).

Where αLAC% = α-linolenic acid content (% of total fatty-acids), SPavTmin = average value for minimum air temperature perceived by the crop during the post-flowering period of maximum sensitivity to high temperature (°C), a and b = empiric coefficients, c = translation coefficient of straight line equation.

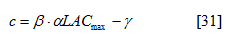

The c coefficient allows to adapt the general equation of straight line proposed by the authors according to the peculiar maximum value of αLAC of tested variety (Equation 31).

Where αLACmax = maximum α-linolenic acid content for the tested rapeseed variety (% of total fatty-acids, parameter), β and γ = empiric coefficients.

In particular, based on experimental data reported by authors, three couples of β and γ parameters were tabulated according to varietal αLAC (high, medium and low) and its response to average minimum temperature within the sensitive period.

Created with the Personal Edition of HelpNDoc: Easily create Web Help sites